Automated compounding represents the future of personalized medicine by transforming traditional pharmacy operations through precision, scalability, and quality control. While personalized medications currently account for only 1% of all prescriptions, pharmaceutical automation enables consistent production of customized dosages crucial for children, elderly patients, and specialized populations requiring tailored treatments.

What is personalized medicine and why does it matter for patient care?

Personalized medicine tailors medication dosages, formulations, and delivery methods to individual patient needs rather than using standardized treatments. This approach proves essential for pediatric patients requiring weight-based dosing, cancer patients needing precise concentrations, and elderly patients with swallowing difficulties requiring alternative formulations.

Traditional one-size-fits-all medications often fail to address unique physiological requirements. Children cannot safely take adult-strength tablets, while patients with rare conditions may need compounded formulations unavailable commercially. Personalized medicine fills these critical gaps by creating medications that match specific patient profiles, improving therapeutic outcomes and reducing adverse effects.

The impact extends beyond dosing accuracy. Patients with allergies to standard excipients benefit from customized formulations, while those requiring multiple medications can receive combination therapies that improve compliance and reduce pill burden.

How does automated compounding transform traditional pharmacy operations?

Automated compounding systems replace time-intensive manual processes with precise, robotic medication preparation that delivers consistent quality at scale. Modern pharmaceutical automation produces up to 1,000 weight-controlled doses per hour compared to manual methods that require extensive preparation time and carry inherent variability risks.

Traditional compounding relies heavily on pharmacist expertise and manual measurements, creating bottlenecks and potential for human error. Automated systems integrate quality control verification at multiple stages, ensuring accurate dosing through digital batch records and comprehensive traceability.

The transformation includes streamlined workflows where pre-programmed formulation blueprints guide robotic systems through precise mixing, measuring, and packaging processes. This standardization enables consistent output regardless of individual operator variations, while freeing pharmacy staff to focus on patient consultation and clinical services.

What challenges does personalized medicine face without automation?

Manual compounding limitations create significant barriers to scaling personalized medicine, including time constraints, quality inconsistencies, and regulatory compliance complexities. Traditional methods require extensive pharmacist time for each preparation, limiting the volume of personalized medications that facilities can produce economically.

Quality control presents ongoing challenges when relying on manual processes. Variations in technique, measurement accuracy, and environmental factors can affect medication consistency. Documentation requirements for regulatory compliance become labor-intensive, requiring detailed batch records and quality verification steps.

Staffing shortages compound these issues, as skilled compounding pharmacists become increasingly scarce while demand for personalized medications grows. Cost considerations further limit adoption, as manual compounding often proves economically unviable for routine personalized prescriptions.

Why is automated compounding the key to scaling personalized medicine?

Automated compounding systems address scalability challenges by standardizing production processes, ensuring consistent quality control, and reducing per-unit costs through efficient workflows. These systems enable personalized medicine to expand from its current 1% market share to potentially 10% of all medications through reliable, cost-effective manufacturing.

Automation ensures regulatory compliance through integrated quality verification systems that maintain comprehensive digital records for every batch. This traceability meets stringent pharmaceutical standards while reducing documentation burden on pharmacy staff.

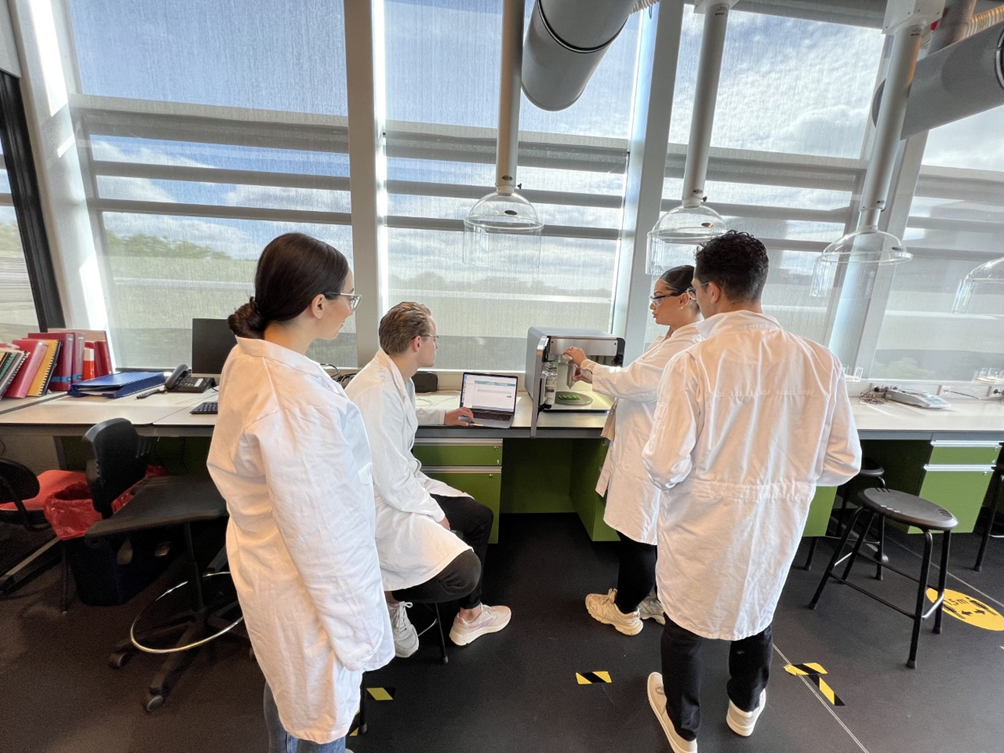

The CurifyLabs Compounding System Solution exemplifies this transformation, combining automated hardware with GMP-manufactured excipient bases and comprehensive quality control tools. Such integrated platforms enable pharmacies to produce personalized medications across multiple formats—tablets, liquids, films, and suppositories—with minimal training requirements and maximum output consistency.

Ready to transform your pharmacy operations with automated compounding technology? Discover how our comprehensive system can help you deliver personalized medications efficiently while maintaining the highest quality standards for your patients.