Transforming Pediatric Care with CurifyLabs' Automated Compounding System

We are thrilled to announce the publication of our latest research, “Automated Extrusion-Based Dispensing: Personalized Dosing and Quality Control of Clopidogrel Tablets for Pediatric Care,” in the European Journal of Pharmaceutical Sciences (November 2024). This study showcases the groundbreaking potential of CurifyLabs’ Automated Compounding System (ACS), powered by semi-solid extrusion (SSE) technology, to revolutionize pediatric medication with precision and efficiency.

Pioneering Personalized Pediatric Medicine

This innovative research highlights how CurifyLabs’ ACS can produce clopidogrel bisulphate tablets tailored to pediatric needs. The tablets, ranging in doses from 2 mg to 20 mg, fill a critical gap in the market, enabling pharmacists to deliver precise, patient-specific treatments. By automating the compounding process, the ACS ensures exceptional reliability, meeting stringent quality standards while simplifying production.

We are proud of our Head of Quality, Farnaz Shokraneh, and the entire team for their dedication to advancing personalized medicine.

Key Advantages for Pediatric Patients

- Personalized Dosing: Tablets can be precisely tailored to individual patient needs, offering flexible dosing for pediatric patients based on factors like weight and medical condition.

- Enhanced Quality Control: Rigorous testing confirmed the tablets’ uniformity, rapid drug release (85% in 15 minutes), and stability over three months, ensuring reliable treatment outcomes.

Key Findings from the Study

-

Precision and Consistency:

- The ACS produced tablets with exceptional mass variation control and uniform drug content, meeting rigorous pharmacopoeial standards.

- Rapid drug release profiles exceeded expectations, with over 85% of the drug released within 15 minutes.

-

Stability and Robustness:

- Comprehensive stability tests demonstrated that the tablets maintained their integrity and efficacy when stored under refrigerated conditions.

- Advanced analyses, such as FTIR and XRD, confirmed the chemical and structural stability of the formulations.

-

Unmatched Customization:

- SSE technology enables effortless adjustments to tablet size and concentration, offering unparalleled flexibility for personalized dosing.

Why Choose Semi-Solid Extrusion (SSE)?

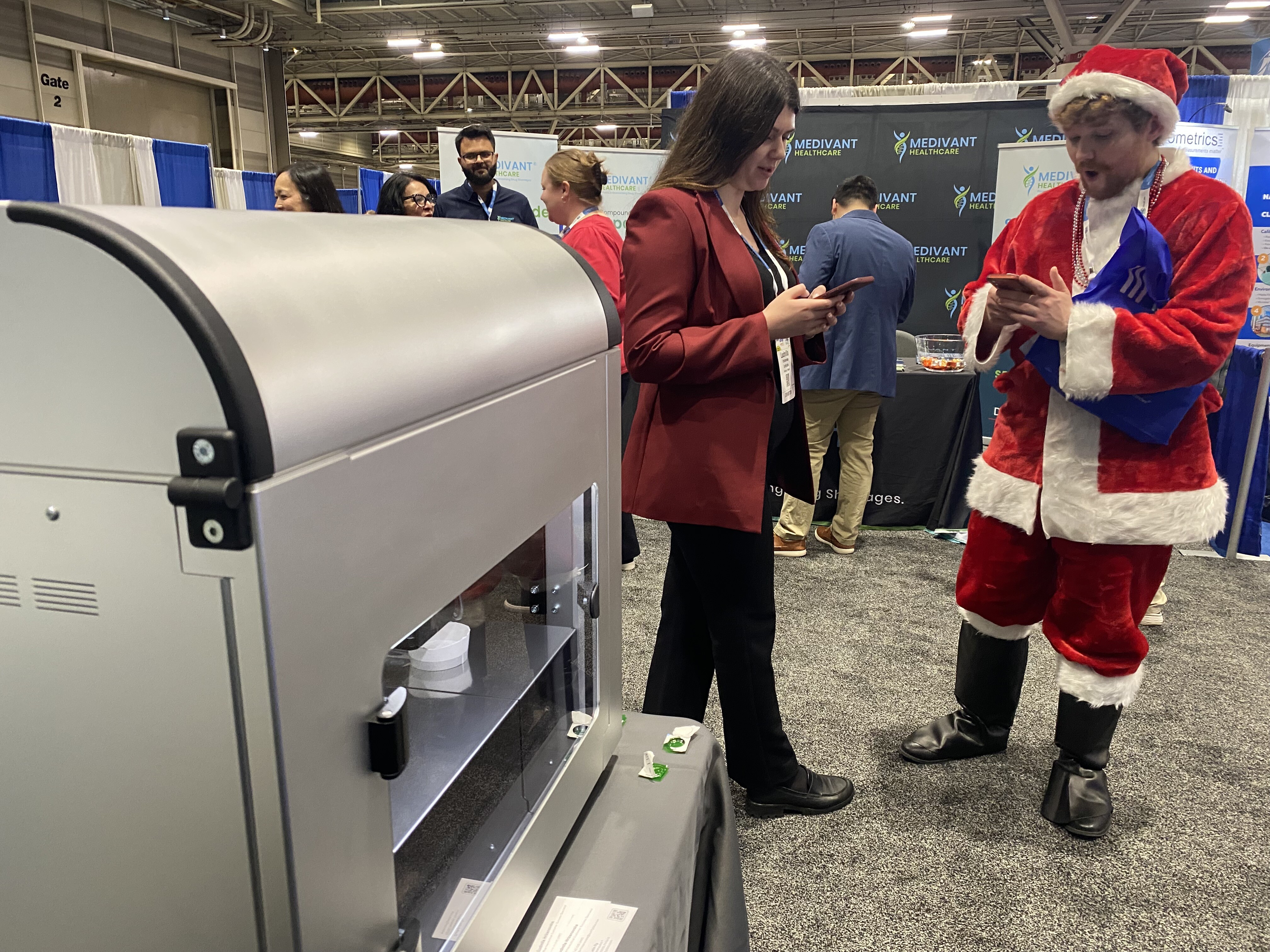

SSE stands apart from traditional 3D printing methods, providing a streamlined manufacturing process without compromising quality. By using CurifyLabs’ proprietary Pharma Printer and CuraBlend®, SSE ensures:

- Compatibility with diverse formulations, including temperature-sensitive ingredients.

- Efficiency in producing immediate-release medications.

- Scalability for various clinical applications.

A New Standard in Pediatric Medicine

This study redefines what’s possible in pediatric care. The automation and precision of CurifyLabs’ ACS ensure consistent quality, addressing the variability often seen in manually compounded medications. For healthcare providers, this innovation translates to safer, more effective treatments tailored to the specific needs of pediatric patients.

Looking Ahead

At CurifyLabs, we remain committed to transforming healthcare through innovation. By combining automation with cutting-edge pharmaceutical technology, we empower pharmacists to deliver exceptional care and improve patient outcomes.

For a deeper dive into this groundbreaking research, access the full study in the European Journal of Pharmaceutical Sciences. Together, we can shape the future of pediatric healthcare.