CurifyLabs’ automated solution for manufacturing personalized medicine is now further validated by a study involving 30 European pharmacies and hospitals.

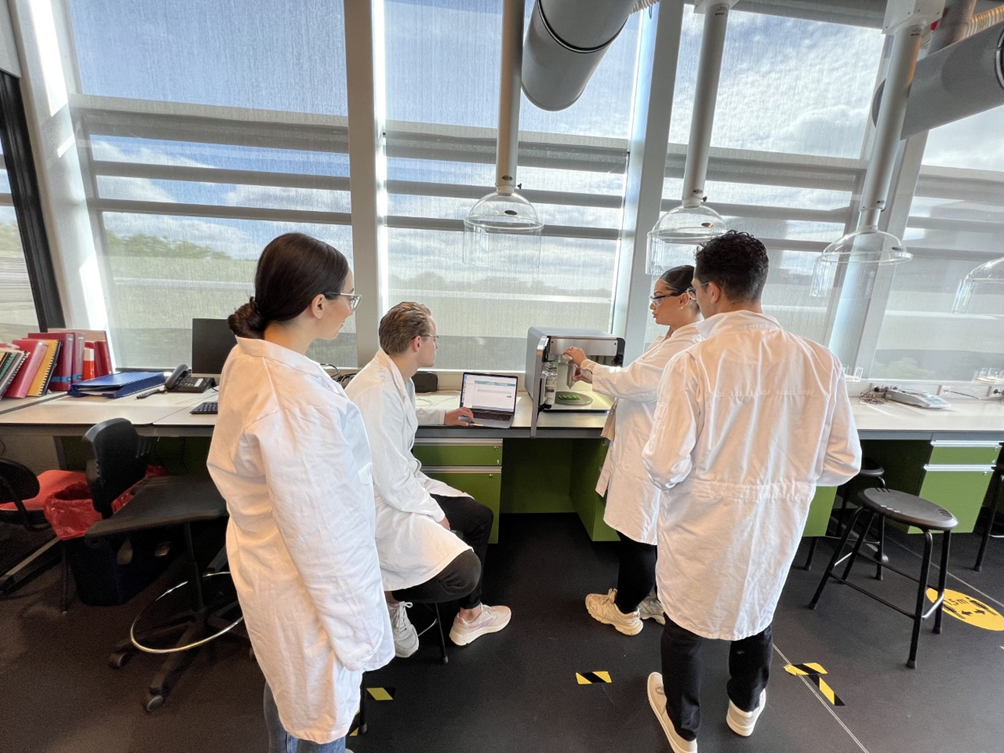

HELSINKI, May 21st, 2024 – CurifyLabs, a leading health technology company providing automated solutions for producing personalized medicine, is marking a significant milestone in the validation of its pioneering automated compounding solution through the first European-wide, peer-reviewed study. The study, conducted in collaboration with 30 European pharmacies and hospitals, examines the automation of compounding oral pediatric tablets using a novel dispensing technology inspired by 3D printing with in-process quality control tools. The results of this study have been published as a peer-reviewed study in Pharmaceutics, a journal on the science and technology of pharmaceutics and biopharmaceutics.

"We are very pleased to achieve this peer-reviewed validation for our pioneering solution. The results indicate that our automated and quality-controlled compounding approach enhances efficiency and quality in the manufacturing of personalized medicine,” says Niklas Sandler, co-founder and CTO of CurifyLabs.

CurifyLabs is leading the technological advancement in pharmacy compounding, the manufacturing of personalized medicines and dosage forms. Traditional compounding methods often involve manual and time-consuming processes, leading to issues in consistency, dosage accuracy, quality control, contamination, and scalability. CurifyLabs is automating the process, making the preparation and delivery of pharmacy-tailored medicines more efficient, faster, and of higher quality and accuracy.

CurifyLabs’ patented Pharma Kit solution combines innovative printable Pharma Inks with automated dosing technology, software, and quality control. In October 2023, CurifyLabs became the first company globally to launch GMP (Good Manufacturing Practice) produced printable Pharma Inks for the manufacturing of personalized medicine.

“As the first in the market, we have successfully combined four technologies to create an effective, easy-to-use automated solution for manufacturing personalized medicine,” says Sandler.

Complying with Diverse International Regulations

Currently, CurifyLabs' solution for pharmacy compounding is being used in 30 pharmacies across 8 countries. Notable users include Charité Hospital, Helios Hospitals, Lausanne University Hospital, and Delpech Pharmacie in Paris. This growing international customer base demonstrates the demand for an automated technology that complies with various regulatory requirements.

"Since day one, we have developed our solution in close collaboration with our clients, the leading European pharmacies and hospitals. This study is the culmination of those collaborative efforts, and it has also enabled us to accommodate the diverse requirements and regulations in each market." explains co-founder and CEO of CurifyLabs Charlotta Topelius. “Furthermore, for pharmacies to consider investing in automated technology as a replacement for manual compounding techniques, the methods must be quick and validated. This underscores the importance of this study and validation.”

.png?width=2480&height=3508&name=MicrosoftTeams-image%20(14).png)

More about the study

- This extensive multi-site study explored the automation of compounding oral pediatric tablets using a novel dispensing technology inspired by 3D printing with in-process quality control tools.

- In total, thirty hospitals and community pharmacies from eight European countries participated in the study. The study conducted between May 2023 and December 2023,

- The study aimed to develop an automated extrusion-based material deposition technology to be used with GMP-manufactured excipient bases to offer a more viable alternative for rapid automated compounding without the restrictions related to speed and user-friendliness of most 3D printing technologies.

- The tests mainly evaluated dosing accuracy, including mass and content uniformity, to demonstrate in-process control of the tablets produced. Secondary evaluations were on the system's user-friendliness and ease of use in a pharmacy setting.

- The study used CurifyLabs' CuraBlend® excipient base, a GMP-manufactured pharmaceutical ink intended for automated compounding applications. A standardized study protocol was performed in all participating pharmacies to test the automated dosing of tablets with variable weights.

- The study was conducted in four different iterative phases. Quality control was integrated into the process using an in-process scale and NIR spectroscopy, supported by HPLC content uniformity measurements. Throughout this study, a total of 6088 propranolol tablets were produced at various locations.

Download article here.

The peer-reviewed article titled “Automated Non-Sterile Pharmacy Compounding: A Multi-Site Study in European Hospital and Community Pharmacies with Pediatric Immediate Release Propranolol Hydrochloride Tablets” was published in Pharmaceutics (Pharmaceutics | An Open Access Journal from MDPI)